Reducing the carbon impact of purchasing: Lifecycle analysis as a strategic tool under ISO 14067

Today, the pressure on organizations to reduce their environmental impact has never been greater. Consumers are increasingly demanding, and regulators are imposing obligations to evolve in terms of environmental responsibility.

Faced with this reality, many organizations are discovering that 70% to 80% of their greenhouse gas (GHG) emissions are generated by their supply chain, i.e. by the products they buy and use on a daily basis.

Whether in manufacturing, the food industry or services, purchasing is often the biggest contributor to a company's climate impact.

ISO 14067 was created in response to this challenge, providing a standardized framework for calculating the carbon footprint of products. Thanks to this standard, organizations can not only identify the critical points in their purchasing process, but also take concrete action to reduce their impact.

This article explores the importance of this calculation, how it is carried out, and the solutions that Global Climate Initiatives (GCI) proposes to help organizations take control of their climate impact.

Thanks to a rigorous assessment of production flows and resource use, ISO 14067 also provides a better understanding of the critical phases in product design. Each functional unit is analyzed to identify overall environmental performance and results, guaranteeing a detailed environmental balance sheet at every stage of the product life cycle.

This approach ensures effective impact monitoring and helps structures to direct their efforts towards continuous improvement.

1. How to decarbonize purchasing?

2. The product life cycle according to ISO 14067

2.1. Understanding the life cycle principle and its calculation

2.2 Cradle-to-gate VS Cradle-to-grave

3. The benefits of calculation applied to purchasing and GCI solutions

3.1. Why is calculating environmental weight crucial for purchasing?

How to decarbonize purchasing?

Calculating the environmental impact of purchasing is a strategic lever for decarbonization. For most companies, the supply chain is a major source of greenhouse gas emissionsemissions, whether through the purchase of raw materials, electronic components or finished products.

👕 Let's take the example of a textile clothing company.

A large proportion of CO2 emissions generally come from the cultivation of cotton (or other fibers), industrial processing, and the eco-responsible design of garments.

Contrary to popular belief, transport, particularly when large quantities are shipped, often represents only a small proportion of the total climate impact of the textile industry's activity. In fact, according to one study, the share of shipping can be relatively negligible compared to other stages of a product's Life Cycle Assessment (LCA).

The fashion industry, meanwhile, emits almost 1.2 billion tonnes of CO2 per year, according to the Global Fashion Agenda.

🍽️ In the food sector, purchasing-related rejections can be particularly marked.

For example, according to the Agribalyse database, the production of one kilogram of beef can generate around 30 kg CO2e, including emissions associated with cattle feed and deforestation for pasture.

This type of data highlights the importance for organizations of decarbonizing their purchasing by selecting more environmentally-friendly suppliers and integrating life-cycle considerations right from the product selection phase.

LCA-based methods can be used to analyze these flows to optimize purchasing processes, while taking into account the resources used and the environmental performance of the service provided by suppliers. Evaluating performance within a well-referenced functional unit will deliver concrete results in terms of sustainability.

The product life cycle according to ISO 14067

🤔 Understanding the life cycle principle and its calculation

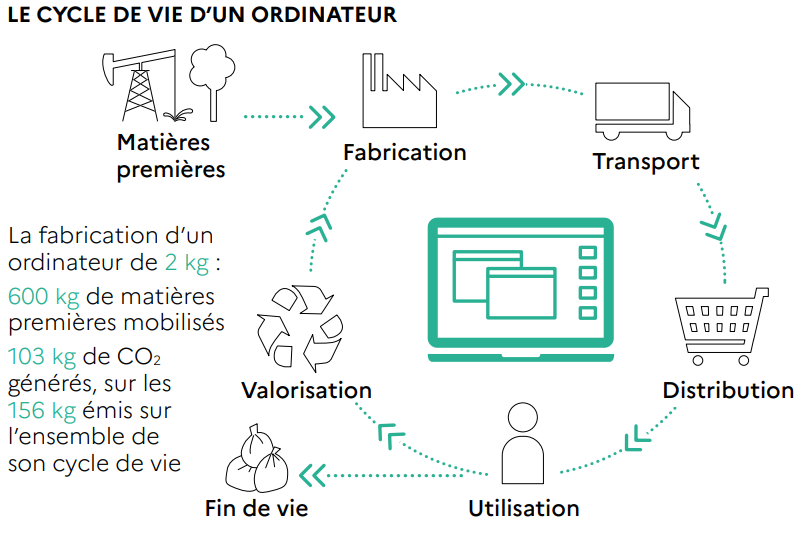

A product's LCA encompasses all phases, from raw material extraction to end-of-life. The ISO 14067 standard makes it possible to measure the environmental impact of a product according to each of these analysis phases.

Calculating the Product Carbon Footprint (PCF) is a key indicator for quantifying a product's environmental impact. This calculation includes not only direct emissions associated with manufacturing, but also indirect emissions linked to material flows and energy processes.

Let's take the example of a high-tech product, such as a laptop. This product goes through several stages before reaching the hands of the consumer:

⛏️ Raw materials extraction: Computer components are mainly made from metals such as copper and lithium, which require a lot of energy to extract.

🏭 Production and assembly : The energy used in factories to assemble these components generates significant waste.

🚛 Transport between production centers and sales logistics centers: The transport of components between creation sites, and then of assembled computers to logistics centers and sales sites, often on a global scale, contributes to global discharges.

💻 Consumer use: Energy consumed during the computer's lifetime is also taken into account.

♻️ End-of-life and recycling: Finally, the waste generated when the computer is disposed of or recycled must be taken into account.

In this case, ISO 14067 would enable an overall assessment of the computer's climate impact, identifying the stages where reductions are possible (for example, by improving energy efficiency during creation or choosing recycled materials).

A thorough study can also reveal underutilized resources and eco-design opportunities. Analytical methods can help to better understand performance and environmental impact throughout the product's LCA, incorporating sustainable design criteria.

🎯Cradle-to-Gate VS Cradle-to-Grave

✅ In certain situations, structures choose to adopt a Cradle-to-Gate approach, i.e. to consider only the stages from raw material extraction to factory exit.

This approach is particularly useful for manufacturers who want to understand the climate impact of their system internally.

✅ In contrast, the Cradle-to-Grave approach also includes the environmental impact of use by the end consumer and the product's end-of-life, providing a more complete picture.

This makes it easier to analyze the environmental performance of products over their entire life cycle, integrating the material flows and processes involved, and providing useful data on services and design choices at every stage.

The results obtained enable a more accurate assessment of environmental impacts, and facilitate the decarbonization of purchasing. Specific training can also be offered to help companies optimize their approach and understand the normative requirements linked to these analyses.

The benefits of calculation applied to purchasing and GCI solutions

🌿 Why is calculating environmental weight crucial for purchasing?

Faced with growing pressure to reduce their greenhouse gas (GHG) emissions, organizations are increasingly integrating environmental criteria into their purchasing decisions.

This is part of a wider strategy called "decarbonizing purchasing". The concept is based on reducing emissions at all stages of product LCA, particularly in the supply chain, which often accounts for a significant proportion of a system's overall climate impact.

The impact of decarbonizing purchasing is particularly visible in certain industries, such as construction, where the choice of materials can significantly reduce environmental impact.

🏗️ For example, in the construction industry, the use of low-carbon concrete can reduce associated emissions by 30 à 50 % compared with conventional concrete. These reductions underline the importance of reliable, standardized data on materials to guide purchasing decisions towards more sustainable options.

By integrating appropriate assessment methods, companies can optimize their procurement processes and improve their environmental performance.

⚙️ The need for standardized data

Calculating the climatic weight of purchases provides a precise, standardized view of environmental impacts, making it easier to integrate environmental criteria into business decisions.

Thanks to tools such as ISO 14067, organizations can precisely quantify the releases of each product or service, taking into account the entire life cycle (from extraction of raw materials to end-of-life). This makes it possible to :

✅ Identify high-impact products and prioritize efforts to reduce waste ;

✅ Compare different purchasing options in terms of environmental impact

✅ Comply with growing regulatory obligations linked to carbon transparency.

📉 GCI and the carbon traceability of purchasing

At Global Climate Initiatives, the carbon traceability of purchases is facilitated by Decarbo'Supply®, a dedicated service enabling the carbon impact of products and services to be measured and tracked precisely. Indeed, Décarbon'Achats® provides access to 90% of a company's emissions reduction potential through the involvement of its suppliers.

This service is immediately available, even if a solution other than GCI is used to calculate their BEGES.

Organizations can specifically manage the decarbonization of their purchasing, with transparency and direct exchanges with their own information systems.

Décarbon'Achats® offers competitive advantages:

🆓 Free for your suppliers : By inviting their customers, suppliers have direct access, free of charge, to calculate their PCF (Product Carbon Footprint, ISO 14 067) online, the "carbon weights" of their products and services.

📋 Meeting the expectations of customers and regulators: Consumers and authorities are increasingly demanding concrete proof of commitment to sustainability. The transparency and traceability provided by Decarbo'Supply® enable organizations to prove their environmental commitment.

🔗 Supply chain optimization🔗: By collaborating with suppliers on GHG emission reduction targets, companies can achieve greener products, while reducing the risks associated with future carbon regulations.

💻 A fluid, intuitive interface and comprehensive support: Personalized guidance, video tutorials, FAQs, online help are available in the GCI Academy to guide and train suppliers. A hotline is also available for support.

Calculating the carbon footprint of purchasing also enables an in-depth assessment of procurement processes. Organizations must regularly evaluate the performance of their actions to achieve their sustainability objectives.

The data collected provides a basis for carrying out an environmental impact assessment, enabling the eco-design approach to be adjusted and procurement methods to be improved. The use of reliable resources and referenced data is essential to guarantee the relevance of decisions taken.

Decarbonizing purchasing is a key strategy for reducing GHG emissions and promoting sustainable practices in the supply chain, thereby contributing to the fight against climate change and the transition to a low-carbon economy.

Calculating the carbon footprint of products and services, in accordance with ISO 14067, is a strategic tool for companies wishing to improve their environmental performance. The environmental footprint of purchasing represents a major opportunity to reduce GHG emissions while ensuring carbon competitiveness. Whether in the manufacturing, food or technology sectors, adopting a Cradle-to-Gate or Cradle-to-Grave analysis helps identify critical points and developeco-design strategies.

Through solutions such as Decarbo'Supply®, GCI supports organizations in their transition to a more sustainable model, providing them with accurate data and facilitating the implementation of low-carbon trajectories. These approaches strengthen the ability of organizations to assess their impact and integrate sustainability criteria into their purchasing decisions, thus contributing to more environmentally friendly eco-design and ongoing assessment of their environmental performance.