A practical guide to calculating a product's carbon footprint using LCA

Like carbon footprinting®, product lifecycle analysis (LCA) is an essential asset for companies wishing to reduce their carbon footprint in a sustainable way, while remaining competitive on the market thanks to thecircular economy.

In fact, from design to end-of-life, a product generates a significant quantity of greenhouse gas emissions, with a potential for reduction that the company must exploit to the full.

Below, we look at how LCA can help us to assess this potential and identify the measures we need to take to produce in a more eco-responsible way.

1. What is Life Cycle Assessment (LCA)?

1.1 The different categories of environmental impact considered in LCA

2.3 The role of emission factors in LCA calculations

3. How to calculate and reduce the carbon footprint of a product or service using GCI?

3.2 Go further with GCI - tailor-made support for an effective decarbonization strategy

What is Life Cycle Assessment (LCA)?

Life Cycle Assessment (LCA) is considered the most advanced and rigorous tool for assessing the global, multi-criteria impact of the production of a good or service, and its environmental repercussions over its entire life cycle, from the extraction of raw materials to its end-of-life (from "cradle to grave").

It examines the various stages, such as manufacturing, distribution, use and disposal, to measure the consumption of natural resources, GHG emissions, air, water and soil pollution, and other associated environmental impacts.

By using LCA, companies and organizations can better understand the environmental consequences of producing their goods, and make more informed decisions about sustainable development and reducing their ecological footprint.

There are 5 key stages in a product's life cycle:

⚒️ Raw materials extraction: This stage involves the extraction of the natural resources needed to manufacture the good, such as mining, agriculture, forestry, etc.

🏭 Manufacturing: During this stage, raw materials are transformed into finished products. It must include processes such as industrial production, assembly, component manufacturing, etc.

🚚 Distribution: Once a good has been manufactured, it is distributed to consumers or points of sale. This includes activities such as transport, storage, logistics and marketing.

🛒 Use: This stage concerns the actual use of the good by consumers. This may include its operation, energy consumption, maintenance and daily use.

🗑️ End of life: At the end of its useful life, a product reaches its end of life. This stage includes the collection, recycling, reuse, repair, disposal and management of waste associated with the good.

It's important to note that the complete cycle may vary depending on the specific product and industry. Some steps may be more complex or involve additional sub-steps.

Product life cycle

🌿The different categories of environmental impact considered in LCA

In LCA, several impact categories are generally considered to assess the complete environmental footprint of a good. Here are the main categories:

⚫ Greenhouse gas emissions: This category is often the most studied in LCA, and the carbon footprint is a key aspect. GHGs emitted mainly include carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O). Carbon footprint assessment quantifies CO2-equivalent emissions over the entire life cycle of a good, including direct and indirect emissions associated with manufacture, use and disposal.

💡 Energy consumption: This category measures the amount of energy consumed throughout the life cycle of the good. It includes the energy required to extract raw materials, manufacture, transport, use and dispose of the good. Energy consumption is often linked to Greenhouse Gases, as the production and use of energy is often associated with the combustion of fossil fuels, which emit CO2.

🌿 Consumption of natural resources: This category evaluates the use of natural resources throughout the entire cycle of the good, including non-renewable resources (such as minerals, metals, oil) and renewable resources (such as water, wood). The depletion of natural resources can have significant environmental consequences, such as the destruction of ecosystems and the degradation of natural habitats.

💧 Water pollution: This category examines the impacts of water pollution resulting from activities linked to the complete cycle of the asset, such as the discharge of toxic substances, chemical goods or polluting agents into rivers, lakes or oceans. Water pollution can harm aquatic biodiversity and ecosystems, as well as the quality of drinking water.

☁️La Air pollution: This category evaluates atmospheric emissions resulting from the complete cycle of the asset, such as emissions of air pollutants (e.g. nitrogen oxides, volatile organic compounds, fine particles) and emissions of toxic substances. These pollutants can have an impact on air quality, human health and ecosystems.

♻️ Waste and waste management: This category examines the quantity and nature of waste generated throughout the entire life cycle of the asset, as well as associated waste management practices (e.g. recycling, incineration, landfill). Inadequate waste management can lead to environmental pollution, soil degradation and health problems.

♻️ What is LCA used for?

LCA is therefore particularly useful for making decisions concerning the entire manufacturing process of a good. For example, the results can be used to visualize the stages of the complete cycle that have the greatest environmental impact, so as to identify areas for improvement aimed at reducing this impact. This makes it easier to find solutions for reducing the ecological footprint of a product. LCA can also be used to address many of the issues we face today.

🎯 The challenges of LCA

🌿 Environmental issues

In the face of the climate emergency, reducing the GHG emissions associated with the production of goods is a key issue. LCA provides invaluable information for making informed decisions on the design of goods, choice of materials, manufacturing processes, modes of transport and so on. It enables us to compare different options and identify the best environmental practices.

🔍 The challenges of transparency

LCA also provides credible and verifiable information on the environmental performance of goods. This information can be communicated to consumers, stakeholders, regulators and other actors involved in the value chain. This promotes greater transparency and enables consumers to make more sustainable choices.

📄 Regulatory issues

LCA is used as a basis for the development of environmental standards and regulations. It contributes to the harmonization of assessment methodologies and facilitates the comparability of results between different goods or services.

How to sustain and strengthen your business through a successful low-carbon trajectory.

How is LCA calculated?

To carry out an LCA it is necessary to follow established methodologies and respect certain key stages.

📚 Methods used

The LCA method is considered standardized, which means that it is governed by the international standards ISO 14040 and ISO 14044. These standards provide detailed guidelines on how to conduct a rigorous and reliable LCA. They are part of the ISO 14000 family of standards governing corporate environmental management.

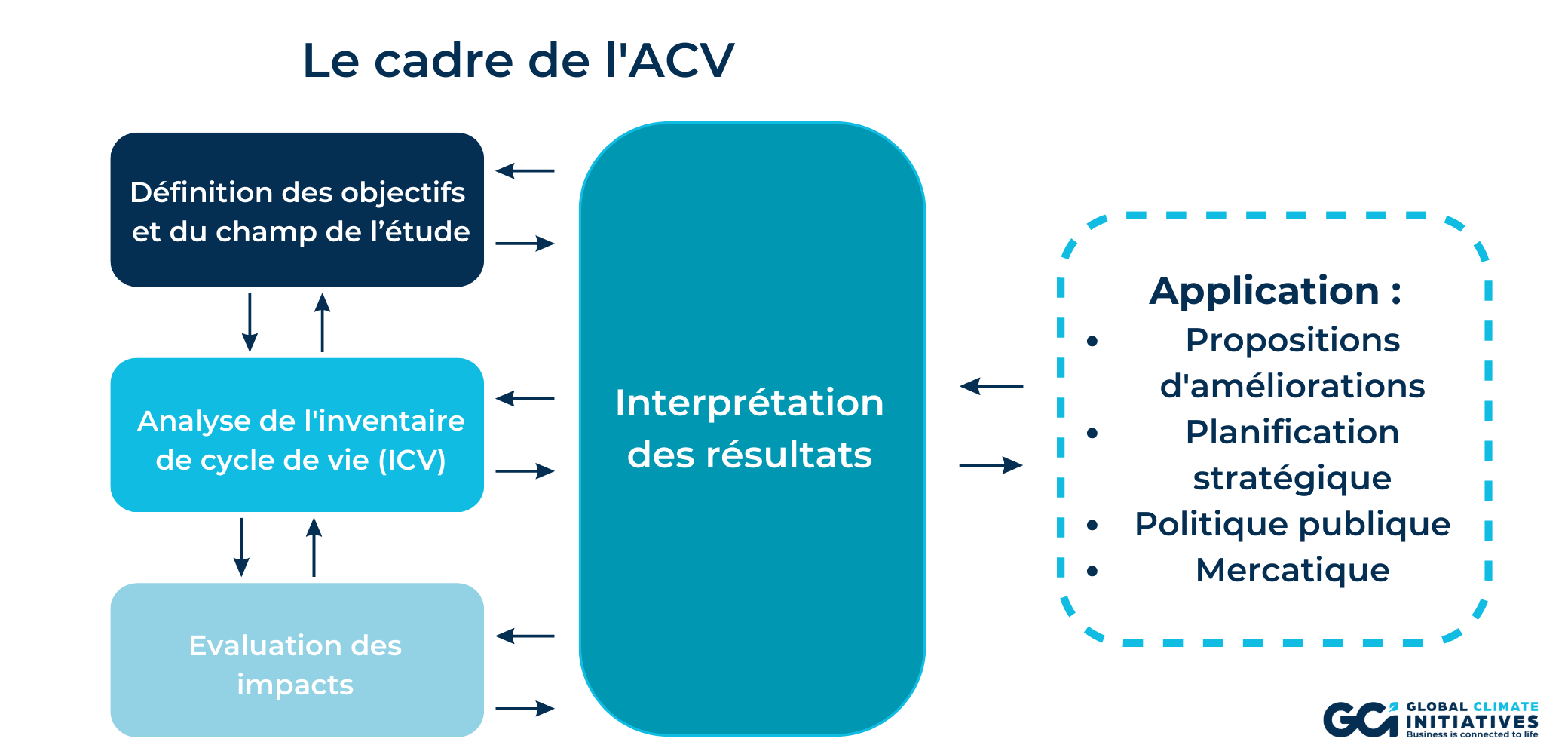

💡 Key stages of an LCA

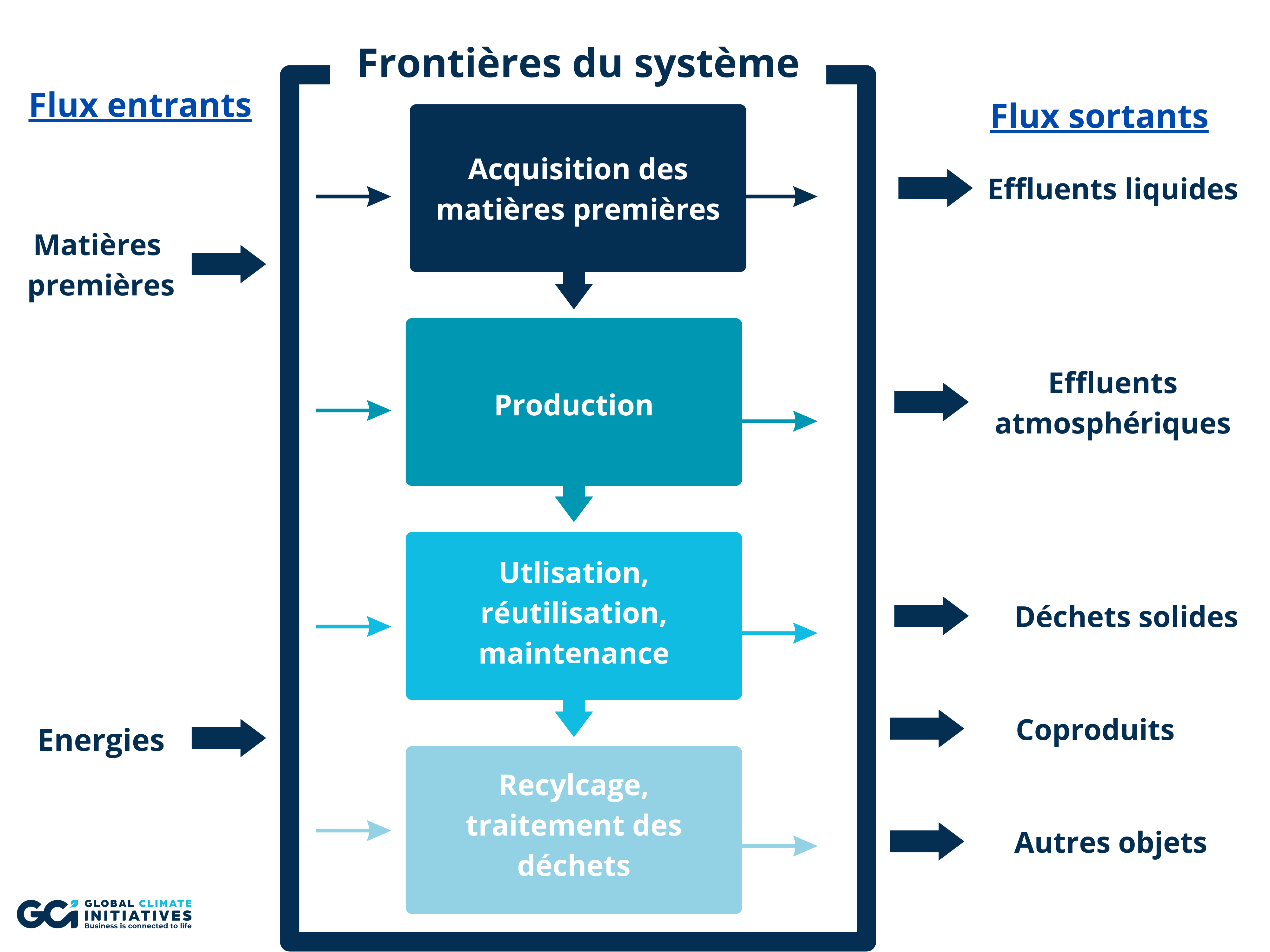

1️⃣ Defining the objective and scope: first of all, it's important to clearly define the objective of the LCA, i.e. what we want to assess. To do this, it is necessary to determine :

The objectives of this evaluation :

- Application (comparison between different goods, eco-design, etc.) ;

- The target or addressee of the study ;

- The "boundaries" of the system under evaluation (i.e. the processes to be included in the system modeling) ;

Functional unity based on 3 criteria:

- product lifespan ;

- quantity and frequency of use ;

- performance.

2️⃣ Life Cycle Inventory (LCI): This stage consists of collecting and quantifying the flows of raw materials, energy and waste associated with each stage in the complete cycle of the good, from the extraction of raw materials to the disappearance of the good.

In LCA, the flows collected are generally grouped into two categories: activity factors and emission factors (EF). Activity factors are quantitative measures such as kilometers traveled, tons transported, energy consumption, etc. They enable us to quantify the resources used and activities carried out at each stage of the process. They make it possible to quantify the resources used and the activities carried out at each stage of the product's life cycle.

As for EFs, they represent the quantities of specific substances or pollutants emitted during the various stages of the complete cycle. For example, this might include nitrogen oxide (NOx) emissions to air, or orthophosphate (PO4) discharges to water. These EFs are used to assess the environmental impact of each stage.

3️⃣ Impact assessment : The data collected in the inventory is then converted into potential environmental impacts. These impacts are then divided into two categories: the midpoint method and the endpoint method.

➡️ The Midpoint method

The Midpoint method aims to quantify the global effects of substances emitted or consumed throughout the entire cycle of a good or service. It focuses on potential problems such as impacts on human health, ecosystems, natural resources and so on.

For example, when it comes to assessing the environmental impact of soil acidification, Midpoint methods can measure this impact using SO2 (sulfur dioxide) equivalents. This makes it possible to quantify emissions of other substances that contribute to soil acidification by converting them into a common unit, thus facilitating comparison and impact assessment.

➡️ The Endpoint method

Endpoint methods in LCA focus on assessing the final environmental damage that may result from the use of a good or service. They focus on direct, perceptible impacts at the end of the causal chain.

These methods assess the potential damage caused by the consumption or emission of certain substances. They are particularly interested in impacts considered to be "endpoints", such as effects on human health, ecosystems, biodiversity, etc. For example, rather than simply assessing GHG emissions, Endpoint methods can assess the more direct consequences of climate change, such as sea-level rise or ecosystem disruption.

4️⃣ Interpretation of results: LCA results are interpreted and used to identify the life-cycle stages that contribute most to environmental impacts. This helps identify opportunities for improvement and optimization.

The 4 stages of LCA according to ISO standards 14040 and 14044

🔍 The role of emission factors (EF) in LCA calculations

CO2 emission factors play a crucial role in LCA calculations. They are used to quantify the emissions of specific substances or pollutants associated with the various stages in the complete cycle of a good or service. These emissions may be linked to the extraction of raw materials, production, use, transport, waste management, and so on.

EFs are substance- or pollutant-specific data, generally expressed in units of mass per functional unit (e.g. kilogram per kilogram of product). They are based on scientific and technical information, often compiled in specialized databases.

When calculating the LCA, EFs are applied to the quantities of raw materials, energy or other inputs used at each stage of the complete cycle. This makes it possible to estimate the specific emissions associated with these activities.

EFs can vary depending on a number of factors, such as the technologies used, energy sources, industrial practices, etc. They are constantly being updated and refined in line with new scientific knowledge and technological advances. They are constantly updated and refined in line with new scientific knowledge and technological advances.

By using the appropriate EFs in the LCA calculation, it is possible to estimate environmental impacts such as GHG emissions, acidification, eutrophication, water consumption, etc. more accurately. This makes it possible to compare the environmental performance of different goods or services, and to identify areas where improvements can be made to reduce negative impacts.

There are 4 types of emission factors:

➡️ Monetary emissions factors: these factors are proposed by ADEME and other international reference bases, and apply to Scope 3 emissions. They considerably simplify the task of entering the GHG balance, but have several disadvantages. Indeed, when using these factors, the company must disclose accounting information to carry out its regulatory GHG balance. These factors are also not very meaningful, as the emissions calculated depend on the prices at which the company has negotiated its energy, goods and services purchases. Inflation therefore inflates a company's Bilan Carbone®! ADEME gives an uncertainty of 80% for these factors and recommends using them only as a last resort.

➡️ Emission factors by type of product and service: these factors are also provided by ADEME and other international reference databases. However, they are only average factors. For example, a T-shirt, which only has one emissions factor in the database, may be produced in Asia or Europe using different processes, materials, and energy sources, which significantly affects the amount of GHG emissions associated with it. Furthermore, not all goods and services are covered by these factors (only 7,000 factors in ADEME's Carbon Database® for hundreds of millions of products and services on the market). They can be used to calculate your initial GHG emissions, but should be replaced as soon as possible with more realistic emission factors, as described below.

➡️ Composite Emissions Factors® (Product Carbon Footprint, PCF, calculated in accordance with ISO 14 067): these factors are based on the detailed composition of a product or service, and take into account the GHG emissions associated with each stage in its life cycle (extraction and transport of raw materials, manufacturing processes, distribution from the factory, use and end-of-life of the product).

➡️ Emissions factors per unit of work (EFUW): these factors are calculated based on the overall carbon footprint of an organization or part of its activity by allocating its GHG emissions to its production units. They enable the different stages of the life cycle to be taken into account accurately.

⚠️ By taking into account the complete cycle of a good, the Emission Factors per Work Unit (EFWU) and PCF are the factors that provide the most complete and representative view of the real carbon impact of a product. They also play a very important role in carbon footprint calculations.

How to calculate and reduce the carbon footprint of a product or service using GCI?

💪 Get your suppliers involved!

In order to encourage its service providers to provide their "Carbon Weight", each has two specific services available:

✅ The "Propagation" Module: This module enables the company to automatically send each of its service providers a request for precise information on their Greenhouse Gas Emission Factors (EFs), and to have access to a monitoring dashboard.

✅ Offer "carbon" analysis tool: This tool enables the company to analyze the carbon impact associated with the supplies or services proposed by suppliers. In this way, it can give preference to those with a lower "carbon weight", thus favoring more sustainable choices.

The GCI platform is therefore the ideal tool for organizations wishing to embark on an effective low-carbon trajectory, since over 90% of the potential for reducing GHG emissions lies with their suppliers!

The GCI platform enables users to calculate customized emission factors for their goods and services themselves, free of charge, in compliance with ISO 14 067: 2018 and the GHG Protocol - Product Life Cycle Accounting and Reporting Standard.

Firstly, the use of GCI has enabled a significant reduction in the uncertainty of the GHG Balance, particularly for scope 3, from 50% to 5%. The Group now has 95% accurate data.

Thanks to supplier data collected and interpreted by the GCI tool, in-depth in-house analyses have been carried out on the impact of 35,000 products, grouping suppliers into 170 families. This represents +80% of purchases in mass and in euros.

Go further with GCI - tailor-made support for an effective decarbonization strategy

Aware that Carbon Competitiveness® is a key asset for companies, GCI has developed a collaborative platform to facilitate exchanges with their suppliers, with a service that enables any company, from very small businesses to major groups, to calculate online, free of charge, the composite emission factor® of the products and services it offers, in full compliance with ISO 14 067 (PCF, Product Carbon Footprint).

In this way, carbon positive discrimination® becomes possible in purchasing, drastically reducing thecarbon footprint of its activities, and thus comply with the Paris Agreements.

To learn more, find out the cost of a carbon footprint assessment and how to use carbon credits effectively.

Our carbon experts will be happy to give you a free free demonstration of our platform. 🚀